Pitless Weighbridge

Pitless Weighbridge

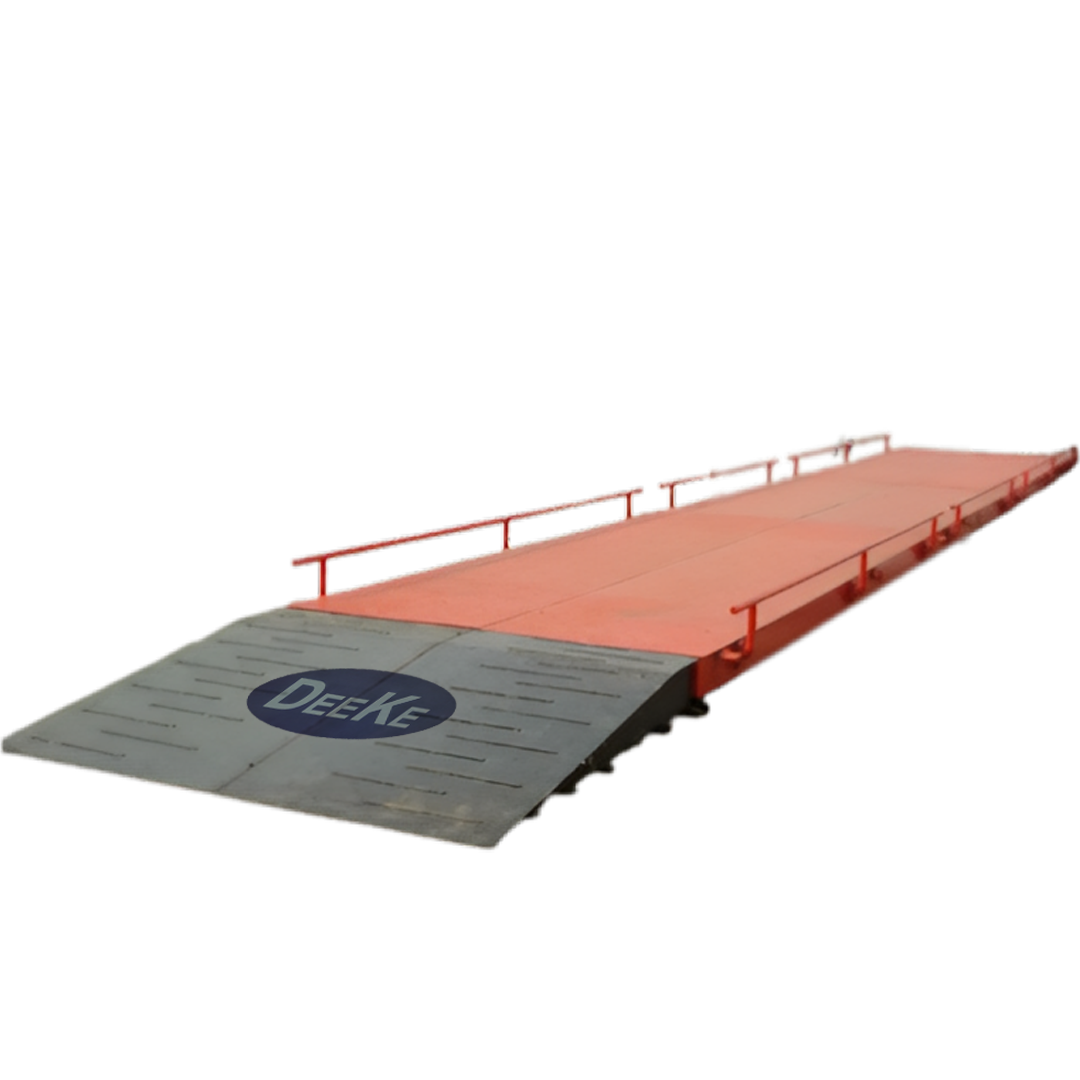

Pitless weighbridges are designed without a pit or depression in the ground. Instead, they have ramps on either side that lead directly to the weighing platform. Vehicles drive onto the ramps, and their weight is measured as they pass over the platform. Pitless weighbridges are suitable when constructing a pit is impractical or when a more flexible setup is needed. They are often used in locations where altering the ground is challenging or in temporary installations.

| Sr No | Model No | Capacity | Accuracy (kg ) | platform size | loadcell |

| 1 | DKWB2OT | 20 t | 5 kg | 3X3 meter | 4 |

| 2 | DKWB30T | 30 t | 5 kg | 6X3 meter | 4 |

| 3 | DKWB40T | 40 t | 5 kg | 7.5X3 meter | 4-6 |

| 4 | DKWB50T | 50 t | 5 kg | 9X3 meter | 6 |

| 5 | DKWB60T | 60 t | 10 kg | 10X3/12X3 meter | 6 |

| 6 | DKWB80T | 80 t | 10 kg | 15X3/16X3 meter | 8 |

| 7 | DKWB100T | 100 t | 10 kg | 18X3 meter | 8 |

| 8 | DKWB120T | 120 t | 10 kg | 20X3 meter | 8-10 |

| 9 | DKWB150T | 150 t | 10 kg | 22X3 meter | 10 |

| 10 | DKWB200T | 200 t | 10 kg | 25X3 meter | 10 |

Pitless weighbridges have emerged as an innovative solution to address the challenges posed by conventional pit-mounted weighbridges. Designed for seamless above-ground installation, these weighbridges provide an efficient and reliable weighing system for heavy loads without the need for excavation.

The elimination of pits not only simplifies the installation process but also optimizes space utilization, making pitless weighbridges an excellent choice for locations with limited space availability. Whether it’s a congested urban setting or an area susceptible to waterlogging, pitless weighbridges offer the flexibility to be set up virtually anywhere.

Manufactured with a sturdy framework and equipped with high-precision load cells, pitless weighbridges deliver accurate weight measurements, ensuring compliance with industry standards. This reliability is vital for businesses involved in logistics, manufacturing, construction, and other sectors where accurate weight data is crucial for operations and regulatory compliance.

Another advantage of pitless weighbridges is their portability. Unlike pit-mounted weighbridges, which are fixed installations, pitless versions can be easily moved and set up at different sites as needed. This feature makes them an ideal choice for businesses with changing operational needs or temporary weighing requirements.

Furthermore, pitless weighbridges require lower maintenance compared to their pit-mounted counterparts. The absence of pits minimizes the risk of debris accumulation, reducing the frequency of maintenance and resulting in cost savings over the long term.

Overall, pitless weighbridges offer a practical and efficient weighing solution, combining accurate weighing technology with space optimization and ease of installation. Their adaptability and reliability make them a preferred choice for industries seeking a modern, hassle-free weighbridge solution for handling heavy loads.

Features of Pitless Weighbridges

Pitless weighbridges are designed to be installed above the ground, eliminating the need for costly and time-consuming excavation work. This feature makes them suitable for locations with waterlogging issues or where building pits is impractical.

As the name suggests, pitless weighbridges do not require pits, resulting in significant space optimization. This makes them ideal for areas with space constraints or where maintaining a pit is not feasible.

Pitless weighbridges are constructed with a robust framework to handle heavy loads and endure constant use. They are engineered to withstand harsh environmental conditions, ensuring durability and reliability over an extended service life.

Equipped with precision load cells and advanced weighing technology, pitless weighbridges deliver accurate weight readings, minimizing errors and meeting industry standards for weight measurement.

The above-ground installation of pitless weighbridges allows for faster setup and easier relocation if required. This advantage is especially valuable for temporary installations or businesses that may need to move their weighbridge to different sites.

Pitless weighbridges require less maintenance compared to their pit-mounted counterparts. The absence of pits reduces the risk of debris accumulation, resulting in reduced upkeep and operating costs.